« Neuere Beiträge Seite 2 von 10 Ältere Beiträge »

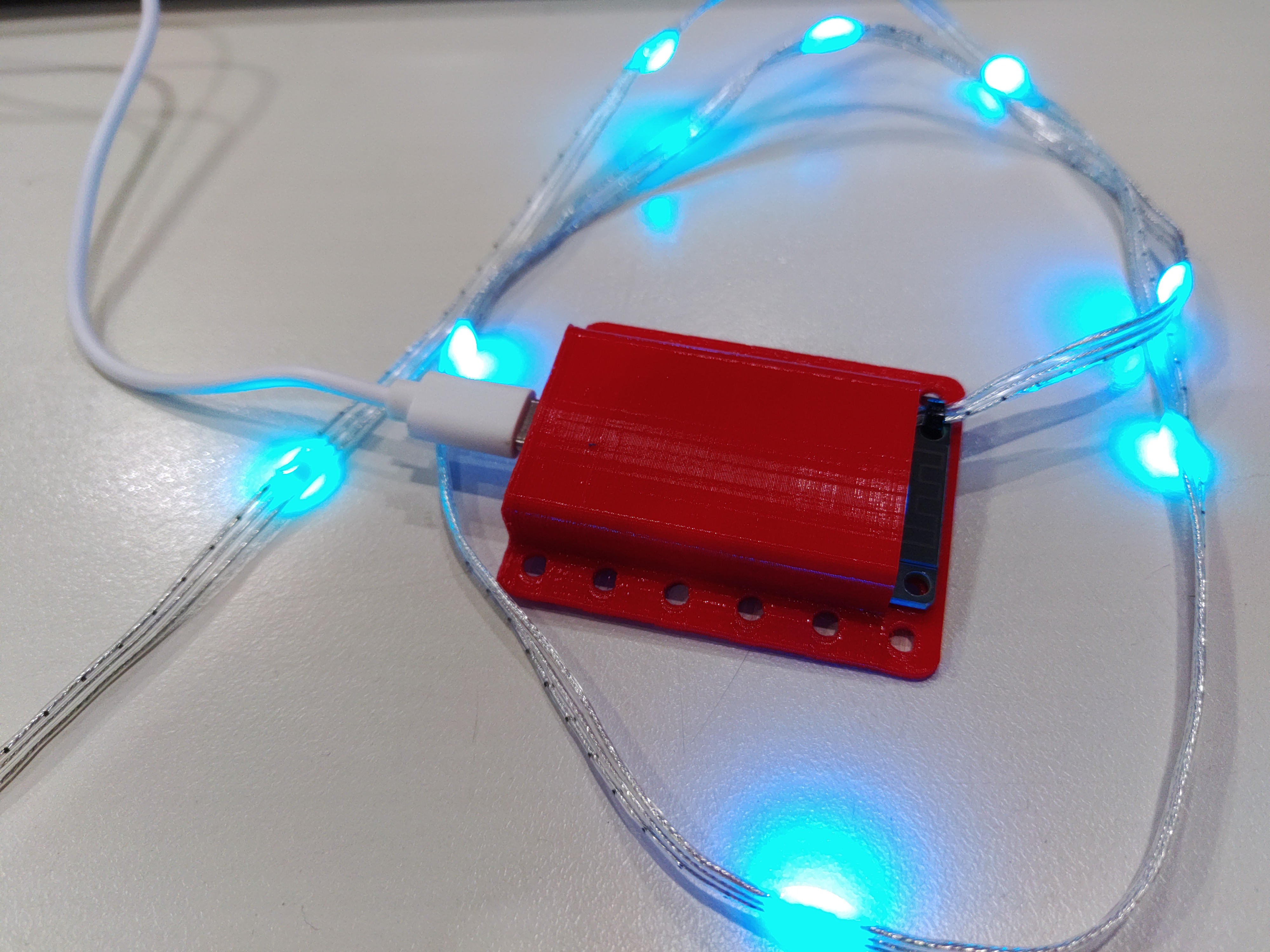

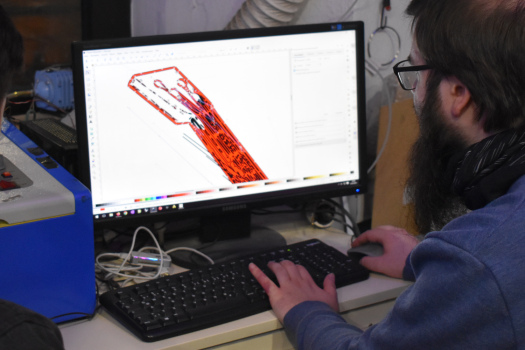

Leuchtklamotten Workshop 2024Kauf der Vereinsräume des C3PB e.V.

Digitaltag 2024

Hallo Liebe Lebensformen und künstliche Intelligenzen

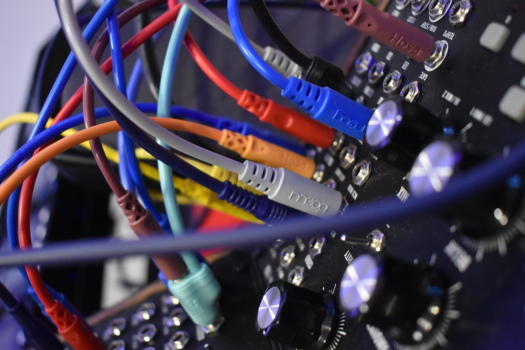

Bilder vom Tag des offenen Hackerspace

Keiner hackt feiner! Besucht uns am internationalen Tag des offenen Hackerspaces!

Safer Internet Day 2023